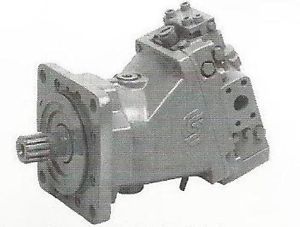

Hydraulic Bent Axis Motor Repair

Hydraulic Bent Axis Motor Repair Specification

- Max Operating Pressure

- 350 bar

- Product Type

- Hydraulic Bent Axis Motor Repair

- Quality Certifications

- ISO Standard Maintenance

- Service Turnaround Time

- 3-7 Days (depending on Condition)

- Service Location

- On-site & Off-site

- Leakage Test

- 100% Pressure Testing

- Repair Service

- Complete Overhaul & Refurbishment

- Rotational Speed Range

- Up to 3600 RPM

- Component Refurbishment

- Cylinder Block, Shaft, Bearings, Valve Plates

- Material Handling

- High-strength steel and alloys

- Inspection Procedure

- Standard Diagnostic and Testing

- Compatibility

- Suitable for Industrial Mobile Equipment

- Applicable Motor Type

- Bent Axis Hydraulic Motor

- Warranty on Repair

- Service-specific warranty available

- Seal Replacement

- OEM Grade Seal Kits Used

About Hydraulic Bent Axis Motor Repair

Our company has immense experience in providing quality centric Hydraulic Bent Axis Motor Repair Service which is also known to be at par with the international standards. One can be confident of receiving world motor repairing services from our end that is channelized with the help of state-of -the-art technology, which plays a vital role in delivering high desired levels of output. We ensure our clients that our Hydraulic Bent Axis Motor Repair Service rendered keeping in mind the growing requirements at pocket friendly prices.

Features:

- In-house performance testing capabilities of all brands of components

- All repairs are backed by an industry leading warranty

- Stringent quality control procedures

Comprehensive Motor Refurbishment

Each hydraulic bent axis motor is meticulously disassembled, inspected, and refurbished by experienced technicians. The service encompasses cylinder blocks, shafts, bearings, and valve plates, using only high-strength steel and OEM-grade components. This rigorous process restores efficiency and extends the operational life of your equipment, meeting demands in industrial and mobile applications.

On-site & Off-site Repair Solutions

We offer flexible repair service locations to suit our clients requirements, providing both on-site servicing for minimal downtime and off-site facilities for complex overhauls. Our specialists adhere to standard diagnostic procedures and ISO-certified maintenance practices, ensuring every repaired motor leaves with guaranteed performance and reliability.

FAQs of Hydraulic Bent Axis Motor Repair:

Q: How is the hydraulic bent axis motor repair process carried out?

A: The process starts with a thorough diagnostic inspection, followed by the complete disassembly of the motor. Key components such as the cylinder block, shaft, bearings, and valve plates are refurbished or replaced with OEM-grade parts. After reassembly, a 100% pressure leakage test ensures operational integrity before delivery.Q: What types of motors are compatible with your repair service?

A: Our service is specifically designed for bent axis hydraulic motors used in industrial mobile equipment and material handling systems. We address motors operating at up to 3600 RPM and 350 bar pressure, utilizing high-strength steel and certified alloys in all repairs.Q: When will my motor be ready after submitting it for repair?

A: Typically, our service turnaround time ranges from 3 to 7 days, depending on the condition of the motor and specific repair requirements. This ensures efficient and reliable restoration without compromising on quality.Q: Where do you provide motor repair services?

A: We offer repair services both on-site at customer facilities and off-site at specialized service centers across India. Our flexibility allows clients to choose the most convenient option for their operational needs.Q: What inspection and testing procedures are followed in motor repairs?

A: Our technicians use a standardized diagnostic procedure to pinpoint issues. After repair, each motor undergoes a rigorous 100% pressure leakage test to confirm it meets safety and performance standards before final handover.Q: How does seal replacement benefit motor performance and longevity?

A: We employ OEM-grade seal kits during refurbishment to guarantee optimal sealing, minimize leakage risk, and enhance overall efficiency and motor lifespan, especially in demanding industrial environments.Q: What warranty do you provide on repaired motors?

A: Each repair comes with a service-specific warranty, ensuring peace of mind for clients. Details are provided based on the scope and nature of the repair, supported by our commitment to ISO-certified maintenance standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry